Intelligent assembly constrains

We have always offered Master´s Thesis opportunities to university students to support their academic and professional qualifications. There are more than 40 Master´s Theses completed for Vertex during the years. The research results are implemented in our product development to provide cutting-edge software solutions for our customers. In the “My Master´s Thesis Journey” blog series, our young professionals tell about their Master´s theses and what they have learned and accomplished during the journey.

A slow start

With a background in mechanical engineering, robotics and software engineering, the initial

challenge in the master’s thesis journey was to determine a topic that would both fit the

hopes and dreams of Vertex Systems, while still connecting to robotics in a meaningful way.

One crucial aspect was to find a topic that would also be interesting to me. Through

numerous iterations and meetings the topic evolved from “Maybe something mechanical

related to robotics…?” to “Could we use machine learning to enhance the mechanical CAD

system?”

Even though this process took some time, it was probably the most important single step in

the thesis journey. I had been interested and involved in machine learning during my studies,

and thus the thesis provided a desirable chance to enhance my own expertise as well.

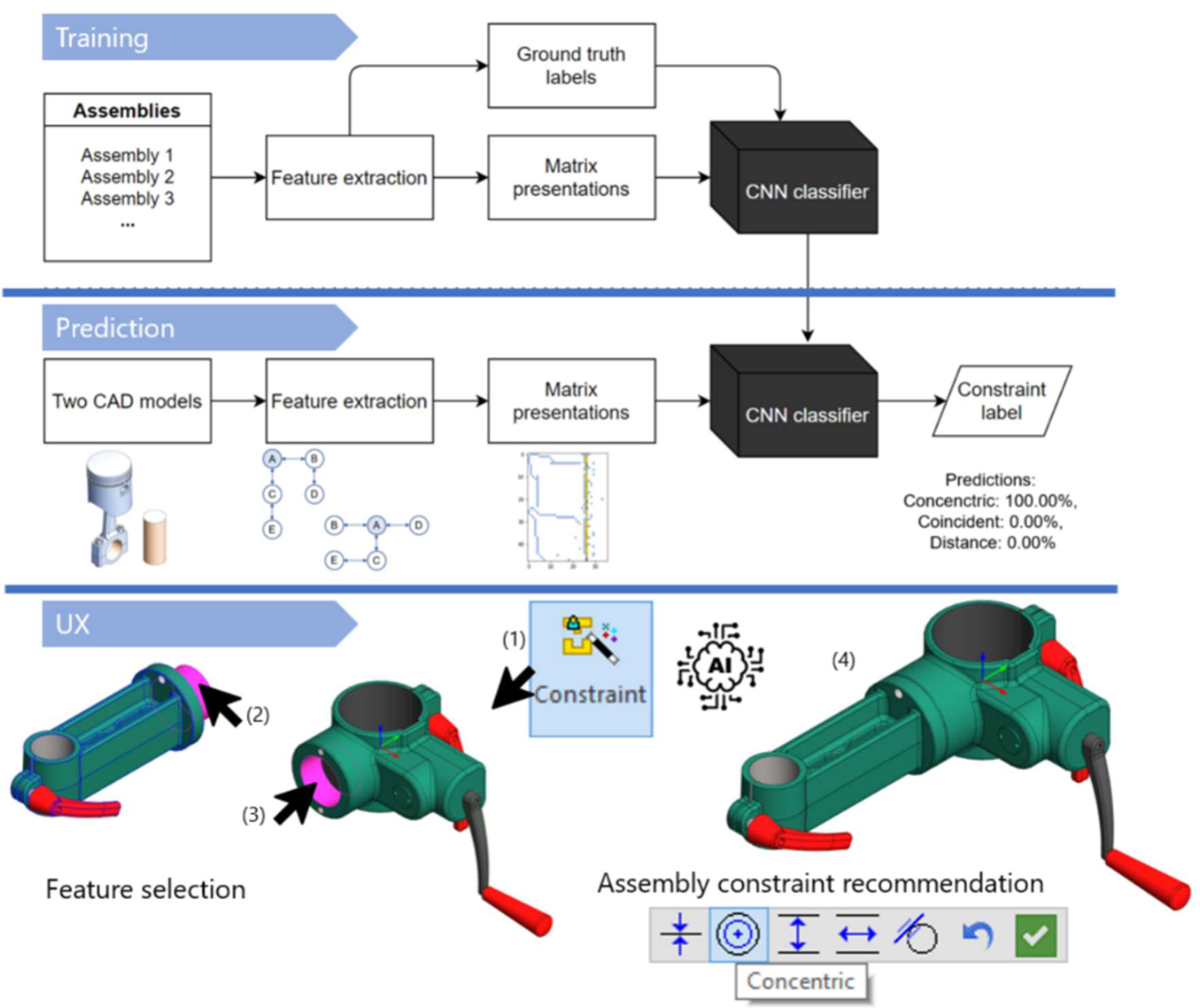

Adding intelligence to CAD assembly constrains

A quote from the abstract of my thesis best summarizes what an assembly constraint and

the demand for this kind of work is:

“Assembly constraints determine the relative position and allowed movements

between CAD models in assemblies, which are an integral part of computer aided

design. They comprise both the expertise of CAD designers and information on the

purpose of the assembly. Automation of the assembly constraint adding process

supports designers by decreasing the design time and enhancing the user

experience.” – Me, 2021

Now that we knew the most fundamental “whats” and “whys”, we can dive in on the “hows”.

To abbreviate, the goal of the thesis was to develop a convolutional neural network -based

classifier that can select the correct assembly constraint from a set pool of constraints, that

best connects two CAD models based on the models’ geometrical properties. The

development of machine learning based systems include some common steps, of which the

main steps that were present in this thesis are: data presentation construction, data

collection, system architecture design and training and validation of the model.

A more in-depth reasoning behind the data presentation and system architecture selections

can be found in my thesis , but for the scope of this blog it is enough to state that an adjacency graph -based matrix presentation was combined with a convolutional neural network architecture for a real-time capable system. Data augmentation was combined with the data collection process to maximize the amount of data. The matrix presentation was honed through training six classifier models, the best of the which reached classification accuracy of 95.46% and was selected for production.

I have always been a visual person so here is what happens under the hood of the classifier

system in ✨images✨. The trained model is used in production to provide probability

predictions of constraint types that go through filtering and are presented to the user through

the bottom-most part of the image.

Enough of the technical mumbo jumbo

Hey you! Yes, you who skipped forward after reading the scary word “convolutional neural

network”. This is a good place to start reading again.

Let’s ponder the process a little. For me, probably the most difficult part of the work was

getting words on the paper. I think this is a common problem in engineering, where doing

things is yay, whereas documenting them is more of a nay. From the get-go I had a vision of

how to implement the system, which lead to there being only minor technical difficulties on

that department. With rigorous planning the problems were conquered and eventually the

thesis finished its final form.

While Vertex has a long history with CAD systems and software development, machine

learning was an entirely new subject prior to the thesis. It was exciting to get to setup the

new machine learning system and everything related to it from scratch. CAD has a lot of

potential for automation and hopefully in the future this potential is utilized to the maximum to

make our customers’ lives even easier.

To wrap up things up

The developed assembly constraint classification system was released as a part of the new

version launch of Vertex G4 CAD during November of 2021. At the time of writing this blog

the feedback has been positive and it will be interesting to hear more about how our

customers like the feature!

Read also Iñigo Flores Ituarte`s blog post! Iñigo was guiding Joonas´ Master Thesis.

Read also other “My Master´s Thesis Journey” blog posts:

AI assisted document archiving